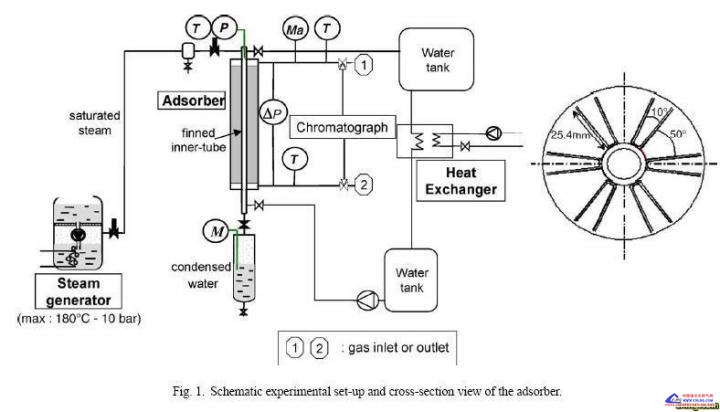

The performances of a recently developed TSA process for gaseous pollutant treatment, based on indirect heating and cooling by means of an internal heat-exchanger, have been investigated both numerically and experimentally. Heating is carried out by condensing steam, and cooling by water circulation. The cycle performances are usually better than those of competing processes, but with increased heat consumption. The sensitivity of the performances to the regeneration temperature and purge flow rates is discussed. Lastly, it is shown that in the conditions of an adsorber scaled-up to a typical practical size including a mass of adsorbent 1000 times higher than in the laboratory column, the specific heat consumption is in the same range as conventional TSA processes.