免职声明:本网站为公益性网站,部分信息来自网络,如果涉及贵网站的知识产权,请及时反馈,我们承诺第一时间删除!

This website is a public welfare website, part of the information from the Internet, if it involves the intellectual property rights of your website, please timely feedback, we promise to delete the first time.

电话Tel: 19550540085: QQ号: 929496072 or 邮箱Email: Lng@vip.qq.com

摘要:design and manufacturing in China. The vacuum brazing furnace in SASPG is the largest in the world. The advanced brazing technology and accurate computerized process control effectively ensure the high brazing quality. Meanwhile, SASPG has introdu..

|

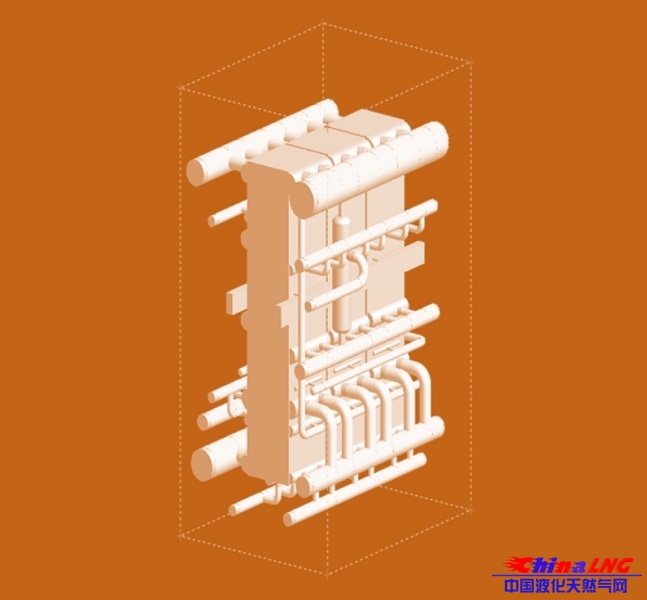

design and manufacturing in China. The vacuum brazing furnace in SASPG is the largest in the world. The advanced brazing technology and accurate computerized process control effectively ensure the high brazing quality. Meanwhile, SASPG has introduced the internationally advanced calculation software for the heat exchangers, the high-accuracy punching machines, the argon arc welding machines, plate shearing machines, the advanced cleaning&inspecting equipment and the heat/mass transfer laboratory. SASPG can design and manufacture the large-sized aluminum plate-fin heat exchangers with the single-core size of 10000×1450×1600mm and the design pressure of 10.0MPa. The annual production capability is more than 3000 ton. SASPG has supplied a lot of aluminum plate-fin heat exchangers used in air separation plants with the capacity of 50~50000Nm3/d, in the 12-480T/d oxygen & nitrogen liquefaction plants, in the 50000~240000 Nm3/d light hydrocarbonsrecovering plants and in the 1,000,000 ton per year LNG project. The heat exchangers with medium and high pressure (highest operation pressure up to 9.2MPa have been already supplied to the petroleum, natural gas and chemical industries. At the same time, the structural packings made by SASPG have been used in air separation industry. The small-sized heat exchangers have been also supplied to the energy, locomotive and electronic industries.

|