中国首套大型LNG储罐内潜液泵开发与工业化测试

责任编辑:cnlng 浏览:474次 时间: 2024-04-10 10:23:33

免职声明:本网站为公益性网站,部分信息来自网络,如果涉及贵网站的知识产权,请及时反馈,我们承诺第一时间删除!

This website is a public welfare website, part of the information from the Internet, if it involves the intellectual property rights of your website, please timely feedback, we promise to delete the first time.

电话Tel: 19550540085: QQ号: 929496072 or 邮箱Email: Lng@vip.qq.com

摘要:摘要为了实现大型LNG储罐内潜液泵国产化,开展了总体结构设计、关键部件设计、强度分析与材料选择、水力模型优化设计、转子动力学分析以及轴向力平衡设计等关键技术研究,成功开发了国内首套大型LNG储罐内潜液泵(额定流量430 m3/h,额定扬程256 m)。该设备完成了水力性..

|

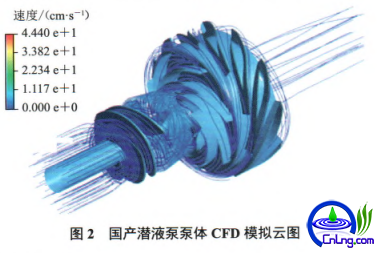

摘要为了实现大型LNG储罐内潜液泵国产化,开展了总体结构设计、关键部件设计、强度分析与材料选择、水力模型优化设计、转子动力学分析以及轴向力平衡设计等关键技术研究,成功开发了国内首套大型LNG储罐内潜液泵(额定流量430 m3/h,额定扬程256 m)。该设备完成了水力性能测试,在低温测试台上进行了LN2低温性能测试,并依托浙江LNG接收站完成了样机现场变流量运转性能测试和长周期可靠性运转试验。结果表明:样机运行平稳,噪声和振动值均满足设计要求;样机低温材料的选取和结构设计合理,在低温环境下的机械性能良好;样机安全保障性能良好,可靠性强;运行参数达到预期设计目标。该设备的成功研制标志着我国对大型LNG潜液泵技术的全面掌握,填补了国内空白,并显著提升了我国LNG装备的技术水平,同时有利于大幅降低LNG关键设备的采购成本和后期检维修费用,具有重要的推广应用价值。In order to realize the localization of large-scale LNG submersible pumps, a series of key technologies were researched, including overall structure design, key component design, strength analysis, material selection, hydraulic model design optimization, rotor dynamics analysis and axial force balance design. Then, the first large-scale LNG submersible pump (rated flow rate 430 m3/h and rated head 256 m) was successfully developed. Its hydraulic performance test was completed and its LN2 low temperature performance was also tested at low-temperature testing bench. The variable flow running performance test and the long-term reliability running performance test were performed on the prototype at Zhejiang LNG terminal. It is indicated that the prototype runs smoothly, and its noise and vibration values meet the design requirements. Its low-temperature materials are selected and designed rationally with good low-temperature mechanical property. The prototype is advantageous with good safety guarantee performance and strong reliability. Its operating parameters reach the design goals. The success of this project marks that China has fully mastered the technologies of large-scale LNG submersible pump, filling domestic technology gaps. And besides, the technical level of domestic LNG equipment is increased significantly, and the procurement cost and the late overhaul and maintenance expense are reduced considerably. This equipment is of great value in popularization and application. 机构地区中海石油气电集团有限责任公司技术研发中心 大连深蓝泵业有限公司 中国石油大学(北京) 出处《油气储运》 CAS 北大核心 2017年第4期435-442,共8页Oil & Gas Storage and Transportation 基金中国海洋石油总公司科研项目"大型LNG储罐内潜液泵国产化联合研制" CNOOC-KJ 125 ZDXM 14 QD010 QD2013 关键词LNG 储罐 潜液泵 低温测试 国产化LNG, tank, submersible pump, low-temperature test, localization 分类号 TE821 [石油与天然气工程—油气储运工程

|

]

]