多台LNG高压泵联动运行的优化与改进

责任编辑:cnlng 浏览:410次 时间: 2024-04-17 10:47:41

免职声明:本网站为公益性网站,部分信息来自网络,如果涉及贵网站的知识产权,请及时反馈,我们承诺第一时间删除!

This website is a public welfare website, part of the information from the Internet, if it involves the intellectual property rights of your website, please timely feedback, we promise to delete the first time.

电话Tel: 19550540085: QQ号: 929496072 or 邮箱Email: Lng@vip.qq.com

摘要:摘要随着我国LNG进口量的不断增加,国内部分大型LNG接收站已开始进行扩建以提高气化外输能力,如何保证新增设备尤其是高压泵的可靠运行以达到预期的效率和产能,便成为LNG接收站重要的研究课题。为此,基于中石油唐山LNG接收站二期工程投产成功运行4年的数据资料,梳理了..

|

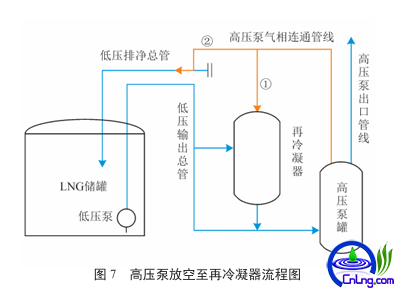

摘要随着我国LNG进口量的不断增加,国内部分大型LNG接收站已开始进行扩建以提高气化外输能力,如何保证新增设备尤其是高压泵的可靠运行以达到预期的效率和产能,便成为LNG接收站重要的研究课题。为此,基于中石油唐山LNG接收站二期工程投产成功运行4年的数据资料,梳理了多台高压泵并联运行出现的相关问题,并根据设计数据、管道布置和联锁保护逻辑,分析了上述问题产生的原因,明确了影响多台高压泵之间流量分配的主要因素,提出了相关操作方式和工艺流程的优化改进措施。研究结果表明:①入出口总管π形弯是导致部分高压泵出现抽液、排液困难的原因;②出口阀开度是影响流量分配骤然变化的重要因素;③高压输出总管LNG倒流是高压泵出口流量被抢占的直接原因;④高压泵泵井与再冷凝器气相空间连通是导致高压泵泵井液位波动的主要原因;⑤提出了优先启动高压输出总管远端高压泵、将高压泵出口阀开度控制在较高水平、投用泵井放空至储罐工艺流程以规避BOG堆积泵井风险、定期检查高压泵出口止回阀的工作状态等4点运行优化措施建议。结论认为,所提出的优化方法可行有效,保证了唐山LNG接收站4 200×10^4 m^3/d的最大气化能力,为LNG接收站扩建工程及新增接收站提供了借鉴。With the continuous increase of China’s imported LNG,some large-scale LNG receiving terminals in China have begun to be expanded to improve their gasification and transportation capacity.Therefore,how to ensure the operation reliability of the new equipment,especially high-pressure pumps,to reach the expected efficiency and capacity has become an important research topic on LNG receiving terminals.In this paper,the technical problems arising from parallel operation of multiple high-pressure pumps were sorted out based on the data of four years'successful operation of the phase II project of the PetroChina Tangshan LNG receiving terminal.Then,the causes of these problems were analyzed according to design data,pipeline layout and interlock protection logic,and the main factors influencing the flow rate distribution between multiple high-pressure pumps were determined.Finally,the measures for optimizing and improving the related operation modes and technological process were proposed.And the following research results were obtained.First,theπ-bend structure of the inlet and outlet header is the reason for the difficult liquid pumping and discharge in some high-pressure pumps.Second,the opening of the outlet valve is an important factor affecting the sudden change of flow rate distribution.Third,LNG backflow in the high-pressure output header is the direct reason for the phenomenon that the outlet flow rate of the high-pressure pump is occupied rapidly.Fourth,the connection between the high-pressure pump well and the gas phase space of recondenser is the main reason for the fluctuation of the liquid level in the high-pressure pump well.Fifth,4 measures for operation optimization are proposed.First,give priority to starting the high-pressure pump at the distant end of the high-pressure output header;Second,keep the opening of the outlet valve of the high-pressure pump at a higher level;Third,empty the in-service pump well to storage tank process to avoid the risk of BOG accumulation in the pump well;Fourth,check the operating state of the outlet check valve of the high-pressure pump regularly.In conclusion,the proposed optimization method is effective and reliable,and it ensures the maximum gasification capacity of 4 200×104 m3/d at the Tangshan LNG receiving terminal.The research results provide technical reference for the expansion of existing LNG receiving terminals and the construction of new receiving terminals. 机构地区中石油京唐液化天然气有限公司 出处《天然气工业》 EI CAS CSCD 北大核心 2019年第9期110-116,共7页Natural Gas Industry 关键词LNG接收站 唐山 高压泵 流量分配 并联运行 止回阀 运转风险 优化措施LNG receiving terminal Tangshan High-pressure pump Flow rate distribution Parallel operation Check valve Operational risk Optimization measure 分类号 F42 [经济管理—产业经济]

|