钎焊接头对铝制板翅结构热应力影响规律

责任编辑:cnlng 浏览:401次 时间: 2024-04-02 09:21:19

免职声明:本网站为公益性网站,部分信息来自网络,如果涉及贵网站的知识产权,请及时反馈,我们承诺第一时间删除!

This website is a public welfare website, part of the information from the Internet, if it involves the intellectual property rights of your website, please timely feedback, we promise to delete the first time.

电话Tel: 19550540085: QQ号: 929496072 or 邮箱Email: Lng@vip.qq.com

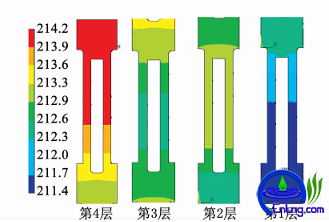

摘要:摘要为保证LNG铝制板翅式换热器安全可靠运行,基于热弹性理论,建立铝制板翅结构热应力分析模型,采用热-固耦合方法,模拟研究实际运行过程中,钎焊接头对铝制板翅结构热应力的影响.结果表明,LNG铝制板翅式换热器,钎焊角曲率半径r=0. 5 mm、融合距离l=0. 137 5 mm时,在靠..

|

摘要为保证LNG铝制板翅式换热器安全可靠运行,基于热弹性理论,建立铝制板翅结构热应力分析模型,采用热-固耦合方法,模拟研究实际运行过程中,钎焊接头对铝制板翅结构热应力的影响.结果表明,LNG铝制板翅式换热器,钎焊角曲率半径r=0. 5 mm、融合距离l=0. 137 5 mm时,在靠近翅片侧和隔板侧钎焊接头处最大等效应力达到峰值,并且最大正应力是引起该位置等效应力达到峰值的主要原因;钎料层等效应力、最大正应力和最大剪应力均变化平缓;在实际运行过程中,靠近翅片侧和隔板侧钎焊接头处,等效应力随钎焊角曲率半径增加而增大;减小钎焊角曲率半径,将降低钎焊接头处热应力变化梯度,从而降低其应力集中程度.靠近隔板侧钎焊接头处等效应力,随融合距离增加而减小,靠近翅片侧的反之;当钎焊角融合距离小于0. 08 mm时,靠近隔板侧钎焊接头处等效应力大于靠近翅片侧的,反之靠近翅片侧的大于靠近隔板侧的.上述研究成果为大型LNG工厂用铝制板翅式换热器的设计、制造以及运行操作提供理论依据.To improve the structural safety of LNG plate-fin heat exchanger,the analysis model on stress of plate-fin structures was established based on thermal-elastic theory.The stress characteristics of plate-fin structures at different brazed joints were analyzed by thermal-stress coupling method.Results showed that the maximum equivalent stress reached the peak value at the brazed joint near fin and plate side when the curvature radius of the brazing angle was 0.5 mm and the fusion distance was 0.137 5 mm,which was mainly induced by the maximum normal stress.The equivalent stress,the maximum normal stress,and the maximum shear stress changed steadily at the brazing seam.The equivalent stress of the brazed joints near fin and plate side increased with the increment of curvature radius on brazing arc.The stress concentration at brazed joints was reduced with the decrease of the curvature radius.The equivalent stress at the brazed joints near plate side decreased when the fusion distance on brazing arc increased,while it was opposite at the brazed joints near fin side.The equivalent stress of the brazed joints near plate side was larger than that near the fin side when the fusion distance on brazing arc was less than 0.08 mm.The above research results provide theoretical basis for the design,manufacture,and operation of LNG plate-fin heat exchangers in large LNG plants. 基金甘肃省自然科学基金(1606RJZA059 1508RJZA109) 国家自然科学基金(51774092 51808275) |