LNG轻烃回收工艺的设计与分析

责任编辑:cnlng 浏览:4239次 时间: 2024-03-22 10:05:31

免职声明:本网站为公益性网站,部分信息来自网络,如果涉及贵网站的知识产权,请及时反馈,我们承诺第一时间删除!

This website is a public welfare website, part of the information from the Internet, if it involves the intellectual property rights of your website, please timely feedback, we promise to delete the first time.

电话Tel: 19550540085: QQ号: 929496072 or 邮箱Email: Lng@vip.qq.com

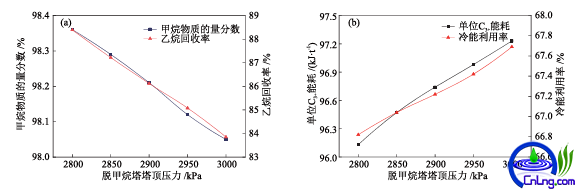

摘要:摘要利用液化天然气(LNG)气化时释放的冷能,结合文献报道的3种LNG轻烃回收工艺,提出了一种新工艺。使用HYSYS模拟软件,热力学方法选用P-R状态方程,对新工艺进行了敏感性分析,确定了最优闪蒸塔入口温度为-105℃、脱甲烷塔塔顶压力为2800 kPa、脱乙烷塔塔顶压力为2000 kP..

|

摘要利用液化天然气(LNG)气化时释放的冷能,结合文献报道的3种LNG轻烃回收工艺,提出了一种新工艺。使用HYSYS模拟软件,热力学方法选用P-R状态方程,对新工艺进行了敏感性分析,确定了最优闪蒸塔入口温度为-105℃、脱甲烷塔塔顶压力为2800 kPa、脱乙烷塔塔顶压力为2000 kPa。通过对比,发现新工艺在甲烷产量、乙烷回收率和设备(火用)分析等方面具有一定优势。Combined with three LNG light hydrocarbon recovery processes reported in the literature,a new process using the cold energy released during the vaporization of liquefied natural gas(LNG) was proposed.Using HYSYS simulation software and P-R state equation for thermodynamic method,sensitivity analysis of the new process was carried out.The optimal inlet temperature of flash column,the top pressure of demethanizer and the top pressure of deethanizer are determined to be -105 ℃,2800 kPa and 2000 kPa,respectively.Through comparison,it is found that the new process has certain advantages in methane production,ethane recovery and equipment exergy analysis. 基金国家自然科学基金(51774237)。 关键词LNG 轻烃回收 甲烷产量 乙烷回收率 (火用)分析 HYSYSLNG light hydrocarbon recovery methane production ethane recovery exergy analysis HYSYS |