As liquefied natural gas (LNG) advances toward widespread commercial use, the prospect of producing it where it will

be distributed commercially has become increasingly attractive.

An invention by the LNG research team at the U.S. Department of Energy’s Idaho National Laboratory has made

this prospect a reality by developing a small-scale methane liquefaction plant.

Small-scale liquefaction plants are advantageous because their compact size enables the production of LNG close to the location where it will be used. This proximity decreases transportation and LNG product costs for consumers.

The small-scale LNG plant also allows localized peakshaving to occur – balancing the availability of natural gas during high and low periods of demand. It also makes it possible for communities without access to natural gas pipelines to install local

distribution systems and have them supplied with stored LNG.

INL liquefaction technology is designed to draw natural gas from a transmission pipeline at a point where the pressure is dropped to accommodate commercial distribution. The plant is powered mainly by the energy created through this pressure

drop. As the gas enters the plant, some of it is allowed to expand, and as it expands, it cools. This allows the process to use the natural gas as a coolant in the liquefaction process.

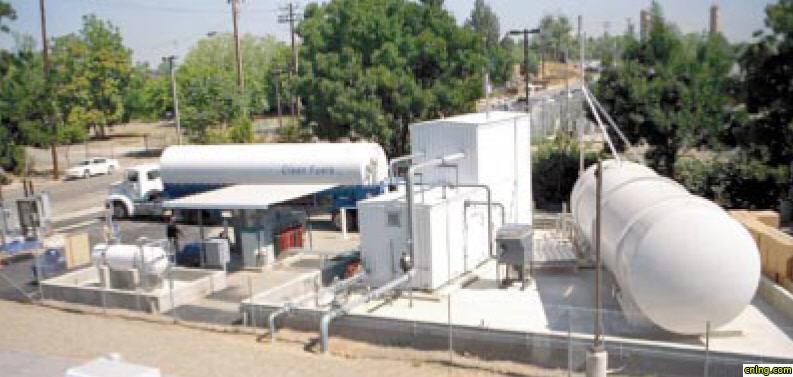

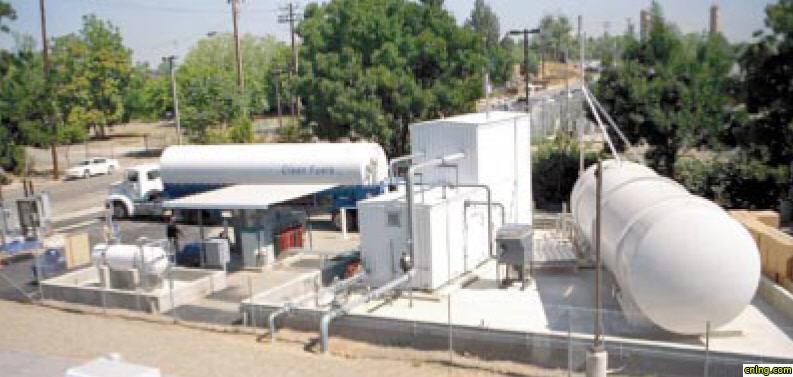

A plant installed in Sacramento removes contaminants from the methane stream as it progresses through the plant.

The stream is injected with methanol, which bonds to the water. When the temperature drops to the point where the

methanol vapor becomes liquid – the water and methanol are separated out of the methane stream. During the final cooling of the LNG product, solid CO2 is formed and separated from the methane stream.

Small-scale liquefied natural gas plants, that draw from existing natural gas lines, are becoming increasingly attractive.