LNG轻烃回收流程模拟及参数优化

责任编辑:cnlng 浏览:561次 时间: 2024-04-18 12:06:29

免职声明:本网站为公益性网站,部分信息来自网络,如果涉及贵网站的知识产权,请及时反馈,我们承诺第一时间删除!

This website is a public welfare website, part of the information from the Internet, if it involves the intellectual property rights of your website, please timely feedback, we promise to delete the first time.

电话Tel: 19550540085: QQ号: 929496072 or 邮箱Email: Lng@vip.qq.com

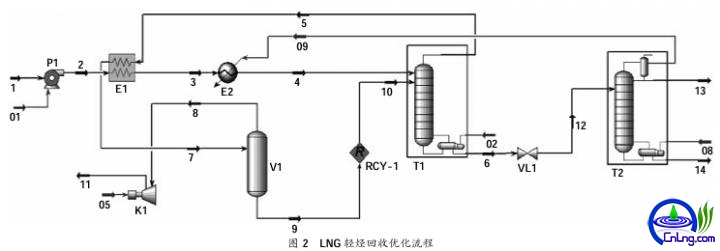

摘要:摘要根据进口LNG中组分的特点及其冷能特性,按照冷能梯级利用的原则和循环处理原理,设计了一种新型的LNG轻烃回收流程,其特点在于循环式结构有效提高了各产品的回收率及浓度,产品后期处理阶段不需要汽化器就可直接进入天然气高压管网。同时分离获得的轻烃产品保持低压..

|

摘要根据进口LNG中组分的特点及其冷能特性,按照冷能梯级利用的原则和循环处理原理,设计了一种新型的LNG轻烃回收流程,其特点在于循环式结构有效提高了各产品的回收率及浓度,产品后期处理阶段不需要汽化器就可直接进入天然气高压管网。同时分离获得的轻烃产品保持低压低温液相,方便产品的储存和运输。本文以进口澳大利亚LNG为例,通过模拟计算和参数优化,与经典工艺相比,优化流程甲烷摩尔含量提高约1.2%,乙烷回收率提高约4%,能耗降低32%。According to the LNG composition and energy features and based on the principle of the step utility of cold energy and circulation process, a new C_2~+recovery process from LNG was designed. In the process, all products are enriched efficiently through the step circulation processes, no BOG(boil of gas) is required and the product natural gas is send into the high pressure pipeline system in gas phase, and the separated C_2~+products is in liquid phase of low pressure and temperature for convenient storage and transportation. Here the simulation and operation optimization are applied to the LNG from Australia, and the optimized process will enrich natural gas by 1.2 %, produce 4 % more C_2~+product, and reduce the energy consumption by 32 %, compared to the classic process. |